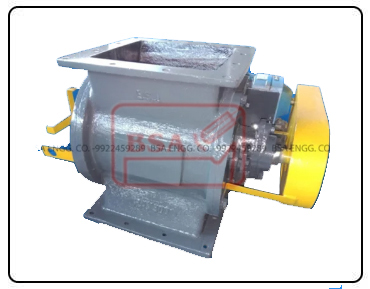

Rotary Valve Manufacturers in USA

We're as proud as to be among USA's most genuine Rotary Valves manufacturers, suppliers, and exporters in USA. We're decades young and wholly devoted to innovation, and we're best at manufacturing the performing rotary valves precision engineered to perfection for multiple purposes in material handling and flow control. Our valves are the industry leaders with pioneer industries due to reliability, precision, and cutting edge-designed and we are first choice business partner for domestic as well as international markets too.

Our Rotary Valves Types

We are one of the best Rotary Valves manufacturer in USA and are supplying better quality of Rotary Valves like::

- Drop Through Rotary Valves

These blow-through rotary valves find applications in vertical discharge and may be included within bag filter units, hoppers, and silos to the highest possible extent. They also include wear-resistant coating on newer models and tighter precision tolerance for reducing air leakage and enhancing efficiency for dust collection applications. - Blow Through Rotary Valves

especially for pneumatic conveying service, the valves provide direct material feeding to the conveyor system. The new designs feature air purge shaft seal and rotor profile designs to ensure improved conveying performance, minimum product carryover, and airtight pressurized operation. - Heavy-Duty Rotary Valves

They are applied in abrasive or coarse-grained particulate matter services such as minerals, cement, grain, and sand. The valves offer zero downtime maintenance and long life because of the efficiency of ceramic-lined internals as well as high-chrome alloys. - Sanitary Rotary Valves

Best suited for use in food processing, chemical processing, and pharmaceutical processing, our sanitary rotary valves offer clean-in-place portability, stainless steel construction, and smooth interior surface finish. Our valves are engineered to meet international sanitation standards such as FDA, CE, and GMP for clean processing and sterilization. - Custom Rotary Valves

We also manufacture and design our own customized rotary valves based on specific requirements like in temperature range, size of particles, work pressure, and material compatibility. Our valves are VFD compatible, automation compatible, and sensor-integrated design to make them cost-effective for use in the new era of industries.

Features of our Rotary Valves

As a leading Rotary Valves supplier company in USA, our all-kinds of Rotary Valves include upcoming technologies like:

- Intelligent Rotor Technology

Rotors are machined exactly in a manufacturing process in which accurate metering devices and system loss are realized. The device is dynamically balanced to run with variable pressure conditions. - Interoperability with Integrated Sensors

These can be offered in IoT schemes, and they can be made to be integrated with smart plant monitoring schemes. Feedback in real time in vibration, torque, and temperature enables them to forecast maintenance much before the system fails. - Energy Efficient Drives

Our valves can be supplied with Variable Frequency Drives (VFDs) through which speed can be controlled for optimal energy efficiency and symmetric material flow. - Enhanced Seal Designs

Enhanced seal designs such as air purge and double-lip reduce leakage and product contamination with cleaner and safer operation even on powder or fine chemicals. - Abrasion & Corrosion Resistance

With the application of the most recent surface treatment and high quality material, our valves function with greater abrasion and corrosive resistances to attain maximum operating life and lessen cost of wear.

Advantages of our Rotary Valves

Our new-generation Rotary Valves in USA, offer variable kinds of advantages such as:

- Improved Performance and Reliability: With guaranteed performance under varying loads and pressure, our rotary valves ensure regulated flow at all times with negligible interference or deviation.

- Minimum Shut-Down and Maintenance: By having externally supported bearings and open housing with modular design, maintenance is quicker and cheaper and unnecessary shut down is eliminated.

- Flexibility of Use: Our rotary valves have been qualitatively proven to be capable of vacuum or pressure conveying system and therefore versatile to be embraced by different industries and materials.

- Clean Operation and Handling Safety: Explosion-proof and dust-proof structure, our rotary valves offer a clean working environment with no risk of cross-contamination in any form whatsoever, particularly for application in the pharma and food industry.

- Industry 4.0 and Automation competitive: Our rotary valves are automation and Industry 4.0-oriented with smart preparedness and install-readiness in next-generation PLC and SCADA systems available to train to integrate with automated production lines and next-generation industrial machines.

Uses Multiplied of our Rotary Valves

Being USA Rotary Valve exporters, our all kinds of services have been supported by another attribute and utilized by all applications such as:

- Pharmaceutical Industry: Our high-containment operation, batch operation, and accurate feeding in clean rooms and all according to GMP practice are provided by our valves.

- Chemical Processing Units: Aggressive chemicals that are at high temperature or high pressure are dealt with by us through the help of higher quality alloys, corrosion-resistant linings, and seal integrity not to leak or be a hazard.

- Plastic and Resin Production: Our rotary valves are traditionally employed in the transporting of plastic pellets, masterbatches, and polymer powders with anti-static advantage and clog-proof operation.

- Agro-Chemicals and Fertilizers: Material dosage determination and corrosion-resistance characteristics then become relevant production issues in fertilizers manufacturing—both of which are betters suited to be provided by our specially treated rotary valves appropriately.

- Food Processing Industry: For effective and hygienic-flowing cleaning process and organized commodity discharge of such materials as flour, spices, and sugar, our sanitary valves are the ones to control.

- Cement and Building Materials: Our abrasion-resistant and steady-operating rotary valves are the best choice in wear-susceptible applications such as cement, lime, and fly ash.

We are one of the leading Rotary Airlock Valve manufacturers, suppliers, and exporters in USA. We're making products that guarantee efficiency, safety, and performance right here at BSA Engineering Company. As USA's leading rotary valve manufacturer, we're dedicated to research, customization, and world-class excellence in service. If your operation requires a rugged, high-tech, and application-based rotary valve, we're ready to provide what you require—with the reliability your operation requires.

-

Our LocationPuneIndiaUAEUSA